This Is Why We Can’t Have Nice Trades

Time to bring back shop class? That’s much easier said than done.

Joe Biden’s announcement last week of a student-loan forgiveness scheme has renewed discussion of whether or not a four-year college is “worth it.” The answer, as ever, is sometimes yes and sometimes no.

What about the skilled trades and vocational education? Amber Athey at SpectatorWorld on Tuesday (probably paywalled) notes, “Conservatives correctly point out that plumbers, electricians, and similar tradesmen can earn just as much as some college graduates. Their training, meanwhile, is a fraction of the cost of a bachelor’s degree.”

Athey adds, however, “we need to be careful about glamorizing manual labor,” noting, “The median salary for a plumber in 2018 was $53,910, or about $10,000 lower than the national median salary and more than $20,000 lower than the maximum salary for President Biden’s student loan forgiveness plan.”

“Skilled trades jobs may have a lower entry fee,” Athey contends, “but this comes with severe tradeoffs,” including a greater physical toll and higher-than-average rates of drug and alcohol abuse.

We can admit Athey makes some good points, without ceding the argument. The reality is, America needs more people working in the skilled trades, not fewer, and that as the work increases in demand, wages and rewards will follow.

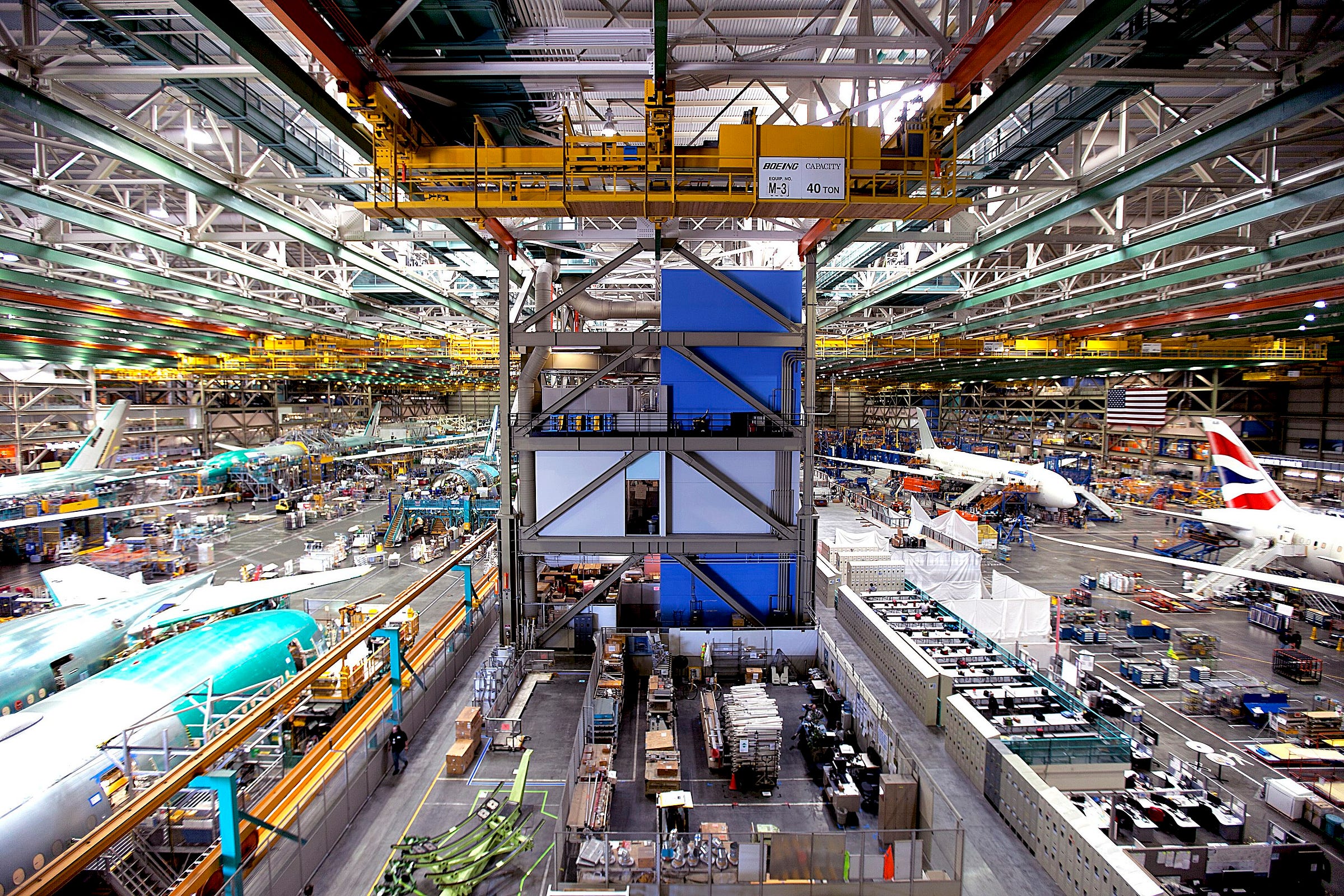

Case in point: The Government Accountability Office earlier this summer revealed that Boeing is having trouble finding qualified workers for its $5 billion Air Force One project. Thanks to COVID-related delays and retirements, the job is understaffed and behind schedule. The aviation giant has already lost $1.1 billion on the job, which was contracted at a fixed price of $3.9 billion. The first of two aircrafts isn’t expected to be delivered until September 2026 at the earliest, CNN reported in July.

Not just any warmblood with a wrench can walk in and get a job assembling the president’s jet. Due to the top-secret nature of the aircraft—two specially converted 747-8s that the Air Force officially designates as the VC-25B—anyone working on the project must undergo an in-depth background check for a security clearance. Because the job involves the president’s life and safety, would-be workers get extra scrutiny. Have they ever been arrested or smoked pot or traveled extensively abroad? That sort of thing.

“Employees must meet stringent security requirements to work on the VC-25B program because of its presidential mission,” the GAO explained in its annual report to Congress on the Pentagon’s sundry weapon systems. “VC-25B officials said that Boeing continues to work with the program office to improve the prescreening process for applicants to ensure timely processing of security clearances.”

Special circumstances aside, Boeing’s workforce challenges speak to a much larger problem. Because aviation workers aren’t just warmbloods with wrenches. They are highly skilled workers in a highly specialized industry. People with the sort of skills Boeing needs are a rare commodity who can command high wages.

The problem, at bottom, is a skilled-worker deficit.

For years now—at least since the Great Recession—America has had far more job openings than it has qualified workers to fill them. And COVID didn’t help. The Bureau of Labor Statistics reports 10.7 million jobs were available at the end of June, down 605,000 over the previous month. So that’s good. But at the same time, businesses hired only 6.4 million workers, which was little changed over the previous two months.

Though the real unemployment rate stands at a relatively low 6.7 percent, the labor participation rate is about as bad as it’s ever been, hovering around 62.1 percent—a number that hasn’t moved very much this year. That has left certain industries, such as construction, manufacturing, and pharmaceuticals, struggling to hire qualified talent. All of those jobs require particular skills.

Yet cultural, social, and political trends over the past three decades or so have emphasized a four-year university education at the expense of the skilled trades, which a person could learn at a community college or vocational school in just a year or two. Though people like Mike Rowe have fought valiantly against the perception that “dirty jobs” are somehow bad jobs, at some point, Americans decided physical labor was disreputable and demeaning. “Do your homework and stay in school,” the message went, “or you’ll end up digging ditches for a living!” Put somewhat differently, why be a sweaty plumber or an electrician when you could pursue a glamorous career in business or advertising or the visual arts? (Why indeed.)

As countless data entry “specialists,” cashiers, customer service reps, and baristas across the country have since discovered, a degree in business or finance or—God help us—philosophy or political science is no guarantee of a corner office and a middle- or upper-middle-class lifestyle. Nevertheless, nearly 60 percent of all jobs in the United States today require a college degree.

That’s dumb.

We’re putting resources and emphasis in the wrong places. Economist Richard Vedder was arguing a decade ago that the United States “overinvests” in higher education—years before the nation’s mounting student-loan debt crisis became a political cause célèbre.

“Some 17,000,000 Americans with college degrees are doing jobs that the BLS says require less than the skill levels associated with a bachelor’s degree,” Vedder wrote in a 2010 essay for the Chronicle of Higher Education.

“Over 317,000 waiters and waitresses have college degrees (over 8,000 of them have doctoral or professional degrees), along with over 80,000 bartenders, and over 18,000 parking lot attendants,” he notes with obvious bemusement.

Surely, we don’t need bartenders with Ph.Ds. But we most certainly do need good plumbers, pipefitters, electricians, steelworkers, welders, fabricators, and machinists, even—especially—as automation and artificial intelligence assume larger roles in our economy. As sophisticated as our technology is becoming, somebody needs to know how to fix those robots. As “perfect” as artificial intelligence may be one day, algorithms—written by human beings after all—cannot do everything. There can be no substitute for human judgment, flawed as it always will be.

Early in his new book, No Apologies: Why Civilization Depends on the Strength of Men, Anthony Esolen recounts the troubling tale of the Colonial Pipeline ransomware attack in May 2021. Russian hackers used a compromised password to insert malware into a vulnerable computer network, forcing the company to shut down its entire 5,500-mile network of pipelines that serve much of the East Coast. The stoppage disrupted fuel deliveries for five days. People lined up for miles to pump rationed gasoline while airlines canceled flights or added stops due to a shortage of jet fuel in the Southeast.

Colonial paid $4.4 million to the hackers to let them bring the pipeline back online.

Bad as that was, it wasn’t the most disturbing part of the story. When Colonial Pipeline CEO Joseph Blount, Jr., appeared before the Senate Homeland Security and Governmental Affairs Committee a month later, he revealed a key reason the pipeline was exposed.

“He testified that most of the men who could operate the controls on the pipeline have died or retired, so that the 5,500-mile line must rely almost wholly upon computerized systems for its operation,” Esolen writes. “That means, of course, that we are vulnerable to attacks by people who do not have to take a guard at gunpoint, or dig a big hole somewhere that no one will notice.”

“[O]ur technology has progressed to the point where, for a time, we can get away with running things on the cheap—and the irresponsible,” he adds. Which is an understatement. As skills are lost and essential trades turn into niche professions, America risks forgetting how to keep the gears of civilization turning. Not just figuratively.

Big Four accounting firm Deloitte reported in May of last year that the “manufacturing industry netted a loss of 578,000 jobs during the pandemic-challenged year 2020—a figure that represents nearly six years of job gains, and yet, at any given moment in the past six months, nearly 500,000 jobs have remained open in manufacturing.” The report forecasts 2.1 million unfilled U.S. manufacturing jobs by 2030. Many manufacturers struggle to find people for entry-level positions, which do not require special skills—just people who can listen, learn, and follow through. How hard can that be?

Yet, the Deloitte report says, “there is no indication whether this trend will reverse.” In fact, the U.S. manufacturing executives Deloitte surveyed said they believe finding the right talent is now 36 percent harder than it was in pre-pandemic 2018. Executives openly fret over what options they may have. “Is there a point when we run out of production workers or a point when we have to consider moving to a different location?”

No single factor can explain the decline in the skilled trades. Companies in the 1980s into the ’90s all but eliminated apprenticeship programs as a way of cutting costs—a decision many have come to regret and attempt to reverse, with limited success.

Changes in the economy played a role. U.S. manufacturing jobs peaked at 19.6 million in June 1979 and have been on the wane ever since. The 2008 Great Recession wiped out 2.8 million manufacturing jobs, many of which never returned.

Automation, obviously, has played a role, as jobs previously filled by humans have been supplanted by robots and machines that never need breaks, never take vacations (except for maintenance downtime), and eventually retire without the need to collect a pension.

Fewer and fewer high schools offer the shop classes that were commonplace in the mid-to-late-20th century. They still exist here and there—even in California. But mostly, they dried up by the early part of this century, subsumed by George W. Bush’s No Child Left Behind law that put reading and math “proficiency” at the center of everything, with the goal of sending more Americans—especially women and minorities—to college. Once schools had to achieve critical benchmarks or risk losing funding, and schools devolved to “teaching to the test,” and shop class was finished.

If it occurred to anyone what policymakers and educators were trading away in the bargain, it couldn’t be less apparent.

Baby Boomer retirements have also removed invaluable experience and institutional memory that would otherwise cultivate the next generations of tradesmen and craftsmen. Related to that, however, is the problem of widespread fatherlessness and family disintegration among the generations that followed the boom. For those of us of a certain age who did have fathers, helping our dads “get the tools,” rotate tires, change oil, replace brakes, and even service air conditioners were sometimes irritating but fairly important rites of passage. (That’s become practically impossible now as auto repair has become the province of computer experts in coveralls.)

Men are not as disposable as our woke culture would like us to believe. As Esolen observes in No Apologies, “boys are not going to learn how to wield a sledgehammer from their mothers.” Sorry, Girl Bosses, it’s true.

Are the skilled trades simply “jobs Americans won’t do”? Why not simply import those workers? Or outsource those jobs? Or both?

Trouble is, that’s exactly what we’ve been doing for nearly four decades—all but obliterating the middle class along the way. As America has become more of a faux “knowledge economy,” we’ve successfully dumbed down at least two generations of people who cannot change a tire, boil an egg, or balance a checkbook. (The good news? Apparently, they like to sew.) We’ve produced millions upon millions of well-credentialed but poorly educated, atomized people who need constant validation through their screens and who recoil from the slightest hint of risk.

America was founded as republic that assumed its people were capable of self-government. Self-government implies self-sufficiency. But the seismic cultural shift away from teaching the trades has helped make us more passive and dependent—less “citizen,” more “subject.”

“What ordinary people once made, they buy,” Matthew B. Crawford writes in his 2009 book, Shop Class as Soul Craft. “And what they once fixed for themselves, they replace entirely or hire an expert to repair, whose expert fix often involves replacing an entire system because some minute component has failed.”

Crawford, a master motorcycle mechanic with a Ph.D. in political philosophy, argues that a passive consumer ethos has transformed Americans’ habits of freedom into habits of conformity and alienation. By restoring a culture in which the trades are once again lauded as respectable, even honorable work, we might begin to restore some of the old habits of freedom and self-government. The goal—or one goal, at least—should be to achieve “a sociable individuality,” one that once again recognizes that we possess rights and duties, and that “we are basically dependent beings: one upon another, and each on a world that is not of our making.”

Knowing that, “the special appeal of the trades,” Crawford writes,

lies in the fact that they resist [a] tendency toward remote control, because they are inherently situated in a particular context. In the best cases, the building and fixing that they do are embedded in a community of using. Face-to-face interactions are still the norm, you are responsible for your own work, and clear standards provide the basis for the solidarity of the crew, as opposed to the manipulative social relations of the office ‘team.’ There are surely other kinds of work that I am unacquainted with where these goods can be realized; it remains for others to explore them.

Crawford has no particular policy solutions to offer. He simply wants his readers to think differently about work and life.

To change the current culture, however, it will be necessary to change some laws. Bringing back shop class would be a start, sure. But loosening other rules would give entry-level workers alternative paths to meaningful work without requiring a four-year degree and an attendant mountain of debt.

An example close to home: My son, who turned 20 in June, attends community college with the idea of eventually pursuing a career in the forensic sciences, possibly as a crime-scene investigator. Last year, on his own initiative, he began contacting mortuaries to ask about apprenticeship opportunities. Two family-owned funeral homes were receptive and sympathetic but had to turn him down. All of the larger corporate mortuaries rebuffed him outright, saying he would need to complete certified mortician’s training before they would even talk to him.

The death business, like so much else in California life, is heavily regulated. Often those rules are well-intended and serve a reasonable public purpose. But as a consequence, many businesses cannot offer apprenticeships even if they wanted to. Could that be changed without undermining consumer protections?

For now, my son works at a distribution warehouse for the largest retailer on the planet. (You know the one.) He’s learning a lot about how to operate robots. He’s being trained in how to solve problems unique to the logistics business. He’s young and vigorous enough to handle the sometimes-long hours and physical demands. But he tells me it is far from mindless work.

I asked him if he might change his mind about forensics. He told me he didn’t think so, but that he planned to stay in logistics work for a while.

“Who knows? It’s interesting work and might lead to some decent opportunities,” he said. “But if none of it works out, I guess I could always move to Ireland and become a sheep rancher.” A noble trade for sure. I just hope it will be in America.

This is a somewhat revised and updated version of an essay first published at American Greatness in June.

"We’ve produced millions upon millions of well-credentialed but poorly educated, atomized people who need constant validation through their screens and who recoil from the slightest hint of risk."

Thank the self-esteem movement.

Yes! Yes, to it all! I have had the great displeasure of watching our once fine country decline from a manufacturer of fine, at least good, products to a horrible culture of, "It's not my job," self-centered laziness. If the coming collapse would bring back some of the resourcefulness and ambition to learning the trades, fixing things, and manufacturing things, I might welcome it. However, with the populace we have now, I'm afraid it would just be the Wild West atmosphere with way more robbery, burglary, and killing.